Features

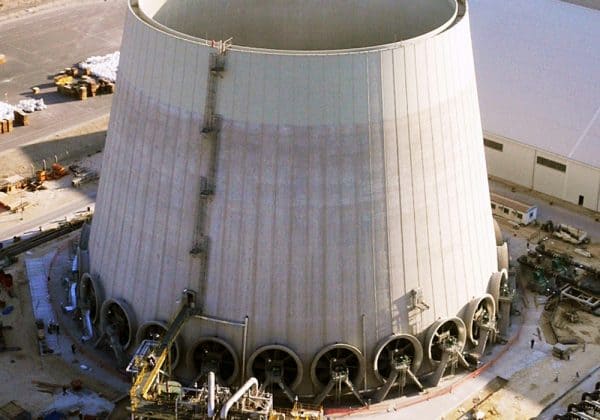

With more than 275 natural draft concrete hyperbolic cooling towers installed and operating worldwide, the SPX team offers you an outstanding source of design, engineering, manufacturing, and construction expertise.

Each cooling tower is custom designed for flow rates up to 200,000 m3/h / 900,000 GPM.

Minimized Operating Costs

Natural draft cooling towers are particularly attractive as a cost-saving solution for larger power stations and industrial plants requiring greater quantities of cooling water. As this type of cooling tower operates without fans, the substantial amount of electric power otherwise required for large cooling tower systems is not needed. The required cooling air is conveyed through the tower by natural draft thus neither fan nor fan power is required.

International Experience of SPX Cooling Technologies

Each natural draft cooling tower is created by a team involving over 200 specialists, including mathematicians, chemical, civil and mechanical engineers, with expertise in soil mechanics, concrete design, hydraulics, heat transfer, materials and machine design.

Treated Exhaust Gas Discharge via Natural Draft Towers

Apart from the advantages of savings in operating costs the natural draft cooling tower can also be applied for the discharge of the treated exhaust gas. That means that neither chimney nor flue gas reheating are required.

Operation in Cold Seasons

Our thermodynamic and hydraulic experts can design cooling towers for reliable operation during cold seasons.