Cooling towers are an essential part of any plant or facility. Cost-effective and energy-efficient, cooling towers come in many different shapes, sizes, weights and materials. The features of your cooling tower vary depending on your plant’s needs and capacity. So which cooling tower arrangement is right for you?

Since 2002, Marley Flow Control has been the industry leader in the manufacturing of cooling towers. We are an Australian-owned and operated brand that offers a high level of expertise and a large range of products that are ready to order. Our wealth of knowledge has allowed us to work with some of the country’s largest businesses and corporations who we are pleased to call our clients.

As industry leaders, we have a high level of expertise and can provide a wide range of cooling tower services. Contact our highly experienced team to discuss your options today. Or read on to learn more about cooling tower arrangements – the different types of cooling towers.

What is a cooling tower?

A cooling tower is a specialised device that discharges heat waste into the atmosphere. This process is done by drawing cool air over the surface of the water. Small amounts of water then evaporate, which lowers the temperature of the water running through the tower.

Cooling towers are used to lower the temperature of the circulating hot water from the condenser or any other heat exchanger. The cooled down water is then ready to be pumped around again back to the heat exchangers.

How do cooling towers work?

Firstly, hot water is distributed over the top of the cooling tower. Nozzles spray the water over the cooling fill – a medium used in towers to increase its surface area. This exposes the water to ambient, cool air.

Using several large fans, cold air is rushed past the warm water, causing some water to evaporate. This evaporation process is what cools the water. The heat leftover is then transferred from the water stream to the air stream, raising the temperature and humidity. The hot air is then released into the atmosphere, leaving behind cooled water.

The water is then collected at the bottom of the tower, ready for the pumps to recirculate cold water through the system again.

Types of cooling towers

Cooling towers are generally classified by arrangement in two ways:

- Forced draft and induced draft

- Crossflow and counterflow

Forced and induced refer to where the fan is located within the tower. Crossflow and counterflow refer to the direction of airflow through the tower’s cooling fill.

Forced draft tower

In a forced draft tower, centrifugal fans are installed on the inlet side, or the tower base. These towers focus the pressure and volume at the fan’s outlet to push air through the tower, creating positive air pressure.

Positive air pressure is the pressure within a system that is greater than the environment that surrounds that system.

Induced draft tower

An induced draft tower has one or more axial fans located at the top of the tower, or outlet side. These fans draw air upwards against the downward flow of water passing through the cooling fill.

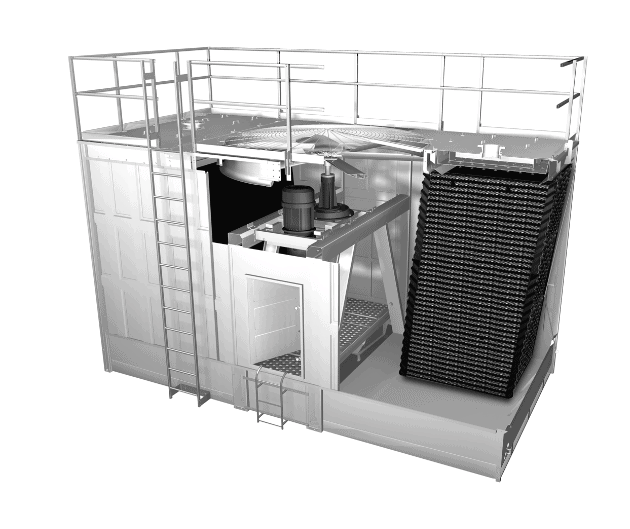

Crossflow tower

Crossflow cooling towers distribute the hot water perpendicularly to the airflow. Water flows from the top of the tower through the hot water gravity distribution basin and into the fill. While this is happening, fans draw air horizontally across the tower’s fill.

Towers requiring splash fill and have large cooling duties will generally be a crossflow tower. While other towers using a film fill and have large cooling duties will be a counterflow tower. Towers with small cooling duties can generally be crossflow or counterflow towers.

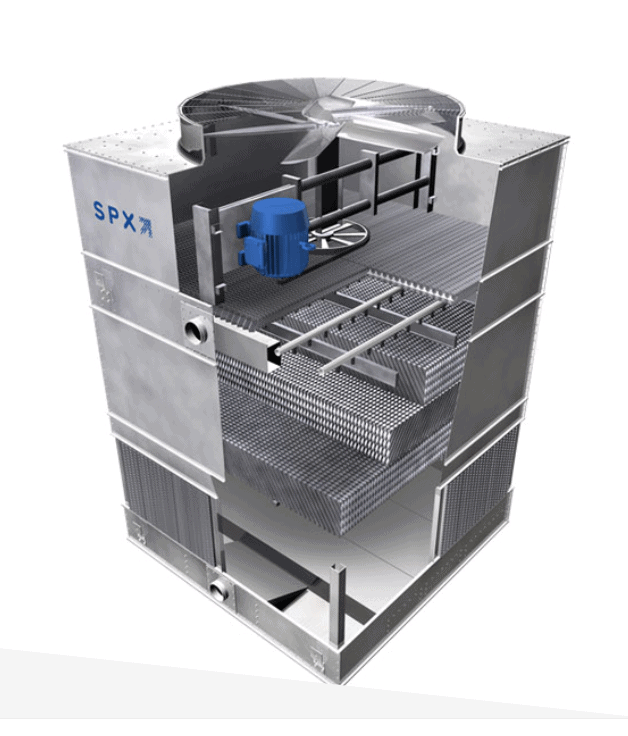

Counterflow tower

Counterflow towers distribute water through pressurised spray nozzles. Like crossflow towers, the water then trickles downward by gravity through the fill.

However, the airflow travels upward through the fill in the opposite direction to the flow of water. Air is drawn from the bottom of the cooling tower, passing over the fill surface and exiting out the top.

How do I choose a cooling tower?

When it comes to cooling towers, there is no ‘one size fits all’. That’s because cooling towers are tailored to your requirements. Each tower has various features and factors that may or may not be suitable for your situation. Some of the considerations are mentioned below.

Forced and induced draft towers

Forced draft towers are only available for very small systems. They also have centrifugal fans, which have violent changes in the air path direction at high speeds. Because of this, a forced draft tower consumes a high amount of energy.

Many building codes allow for higher kilowatt energy levels to accommodate forced draft towers. This isn’t always a good thing, as it encourages people to continue using their inefficient tower.

Induced draft towers come in a full range of sizes and are far more efficient than forced draft towers.

Crossflow and counterflow towers

Maintenance access is one way that crossflow and counterflow differ. For example, If a crossflow tower is seven meters in length or more, a technician can stand upright within the structure while performing maintenance on the fan and motor drive.

Counterflow towers smaller than two meters squared allow a person to reach the fan and drive while remaining outside the tower. However, when the counterflow tower is sized between two meters and seven meters, the tower is too large to reach the mechanical equipment, yet too small to stand inside.

When it comes to crossflow and counterflow towers that are over seven meters, mechanical maintenance is virtually equivalent. Both types require similar platforms which may be temporary or permanent.

Another way in which crossflow and counterflow towers differ is in the variety of fill media types they can accommodate. Counterflow towers accommodate a greater variety of clog-resistant film type fills, which may be useful for customers with moderate to poor water quality.

Which tower is right for me?

Many people believe that one type of tower is superior to others. But this is not always the case. The tower you choose for your facility depends on your needs and constraints.

Marley Flow Control is one of Australia’s leading cooling tower manufacturers, suppliers and repair technicians. Australian owned and operated, we have the experience to deliver the right solution for your cooling tower needs.

We offer a wide range of turnkey cooling tower solutions suitable for all situations – from air conditioning to large-scale industrial processes. As the SPX (Marley) agents in Eastern Australia & NZ, we represent the world’s only ‘full-line’ cooling tower manufacturer solution. Our team can assist with cooling tower design, supply and maintenance. So contact us here to find the right solution for your business.

Find out how we can use our engineering experience to help find the right solution for your business needs. Contact us here for a free quote.